Compatible materials in the construction of lifting electromagnets

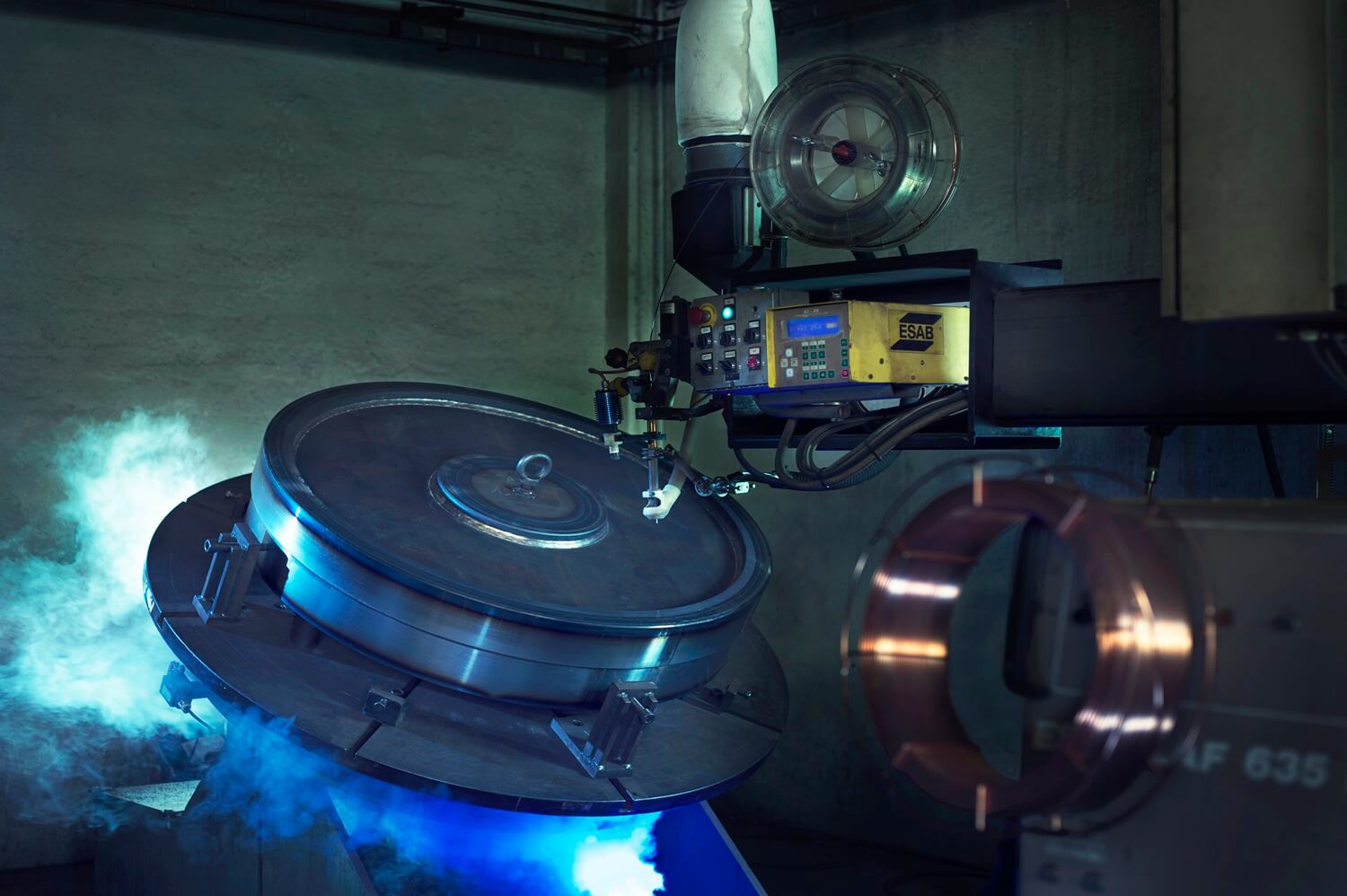

In the industrial sector, theory is the solid foundation upon which everything is built: either something works, or it becomes a problem. And when it comes to lifting electromagnets, this notion becomes even more straightforward. These are devices that move tons of scrap, steel, sheet metal, and bars on a daily basis, often in environments where dust, heat, humidity, and wear are relentless. And yet, they keep going. Why? Because they’re built properly. And above all, because they’re made with the right materials.

But what is a lifting electromagnet made of? Which materials are best suited to its construction? And why those materials rather than others?

Inside the casing of a lifting electromagnet, there is no room for improvisation. Low-carbon steel, manganese steel, resin-coated aluminium windings, each component is the result of engineering precision, field experience, and extensive real-world testing cycles. Because manufacturers of these tools can’t afford a failure at the wrong moment. And neither can the people who rely on them.

Let’s delve into the heart of an electromagnet, examining each material, each alloy, every component that not only ensures efficiency but also resilience, durability, and safety. This isn’t just a technical overview. It’s a practical, straightforward guide for companies and operators looking for real dependability, and for a partner that delivers support, quality, and consistency. Because choosing the wrong material can be expensive. But choosing the right one makes everything work better.

What is a lifting electromagnet made of?

At first glance, it looks like a solid block of metal, strong and quiet. But inside, a lifting electromagnet hides a perfect mix of materials science, smart engineering, and real-world industrial know-how. It’s a quiet technology, but it deserves attention. Every detail matters. It’s the difference between a safe lift and an expensive breakdown.

The working principle is simple but powerful. When electric current flows through a coil, it creates a magnetic field. A ferromagnetic core boosts this field. The result? It can attract and hold metal objects weighing hundreds or even thousands of kilos. It all happens in seconds, and it has to be precise.

But behind this simple action lies a complex machine. Each part does its job perfectly. Here’s what it’s made of:

- Ferromagnetic core: The core is the system’s heart. It becomes magnetised and creates the pulling force. It’s usually made of low-carbon steel for quick magnetic response.

- Coil winding: This is the wire coil, made of aluminium or copper. When current passes through, it generates the magnetic field.

- Magnetic case: A steel shell that protects the inside parts. It’s built to handle shock, heat, and mechanical stress.

- Wear-resistant bottom case: This part is made of manganese steel. It’s the first to touch the material being lifted. It handles impact and abrasion. But it also controls the magnetic field. Since it’s non-magnetic, it helps focus the field at the bottom of the magnet, right where it’s needed. Without it, the field would spread and lifting would fail.

- Coupling system: This could be a steel chain or a special bracket. It depends on the machine and the job. Both offer strength and safety.

- Resinous insulation of the winding: A resin coating protects the coil. It keeps out moisture, absorbs shock, and handles heat changes. This helps the magnet last longer, even in tough conditions.

Each part has a purpose. The way they work together makes the electromagnet reliable, strong, and long-lasting. Nothing is random. Everything is tested and built to perform. Knowing how it’s made helps you choose the right one, and get the best results from every lift.

Ferromagnetic core: the heart of the electromagnet

Inside every lifting electromagnet, there is one key point where all the energy comes together. That point is the ferromagnetic core. It’s where magnetism begins. It’s where the magnetic field created by the coil comes to life and turns into a lifting force strong enough to defy gravity.

Which material makes this possible? Soft iron, and not by chance. Mild steel is the most effective and strategic choice for building industrial electromagnets. It offers three essential advantages:

- Very high magnetic permeability: It acts like a fast lane for magnetic flux. It allows the field to focus where it’s needed, with minimal loss.

- Low coercivity: When the power is off, the material demagnetises almost instantly. This prevents residual magnetism that could cause safety issues when releasing the load.

- Excellent workability: Mild steel is easy to machine and process. It speeds up production and ensures consistent quality, even at scale.

The core is often completed with pole shoes. These are crucial parts that guide and focus the magnetic field. They act like “force channels,” helping to target the attraction zone and increase grip on metal parts. This makes all the difference when lifting irregular, dirty, or mixed scrap, which is common in demolition and recycling work.

Electrical winding: conductivity and strength

Inside a lifting electromagnet, every part has a clear role. But if there’s a starting point, it’s the electrical winding. This carefully coiled wire around the ferromagnetic core, is what turns electric energy into magnetic force. It’s the key to lifting tons of ferrous material with precision.

The winding is made of aluminium wire. Aluminium is chosen for its good conductivity, low weight, and long-term stability. When direct current flows through the winding, it creates a magnetic field that energises the core. The result is a strong, controlled force that lifting companies can rely on.

Other components: strength, protection, and safety in each detail

Besides the core and the winding, a lifting electromagnet includes structural elements. These are designed to handle stress, resist external conditions, and ensure safe, long-term use.

The magnetic case is made of structural steel. This material offers a good balance between magnetic performance and mechanical strength. The outer shell protects the inner components and keeps the magnetic field stable.

The bottom case, which takes the most hits during loading and unloading, is made of wear-resistant manganese steel. This steel is known because it can handle constant stress, helping the system stay efficient and last longer.

For lifting, the electromagnet can be fitted with one of two options:

- A lifting chain, made of alloy steel, built to carry heavy loads safely.

- A bracket, made from structural steel, designed with precise engineering to ensure stability and safety during all lifting phases.

In conclusion, the resin-coated winding adds vital protection. This special coating shields the coil from impacts and stress, helping it last longer. It also offers thermal insulation and resistance to moisture and external agents. That means steady performance, even in tough working conditions.

So, what is a lifting electromagnet made of?

The operation of a lifting electromagnet relies on a principle that’s simple but highly effective: generating a temporary magnetic field strong enough to attract ferrous materials. This process is possible thanks to two main components that work in perfect harmony.

The first is the ferrous core, the central part of the structure. It’s made from a ferromagnetic material and includes pole shoes, special surfaces that direct the magnetic field outward. These pole shoes, thanks to their polarity, help the magnet focus its strength where it’s needed most, boosting lifting power.

The second key part is the electrically conductive winding, a coil wrapped around the core. This winding, usually made of aluminium or copper, carries direct current. As the current flows, it generates a magnetic field that magnetises the core.

It’s this interaction between the core and the winding that activates the magnet, turning electric energy into magnetic force. The result is a tool capable of lifting, holding, and releasing ferrous materials with great precision.

The materials used to build lifting electromagnets are never chosen at random. Each one, whether it’s mild steel, manganese, aluminium, or alloy steel, plays a specific role to ensure high performance, reliability, and safety. For industrial lifting companies, choosing a supplier who truly understands these details, like Zanetti Magneti, is a strategic decision that directly affects productivity.

Looking for high-quality, long-lasting electromagnets? Discover our full range of lifting electromagnets. To learn more, we also recommend reading our article on how they work, their benefits, and where they’re used. Enjoy the read!

Need advice or more details? We’re here to help you find the best solution for your operational needs.